|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Helical Crayford Focuser Model HC-2 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

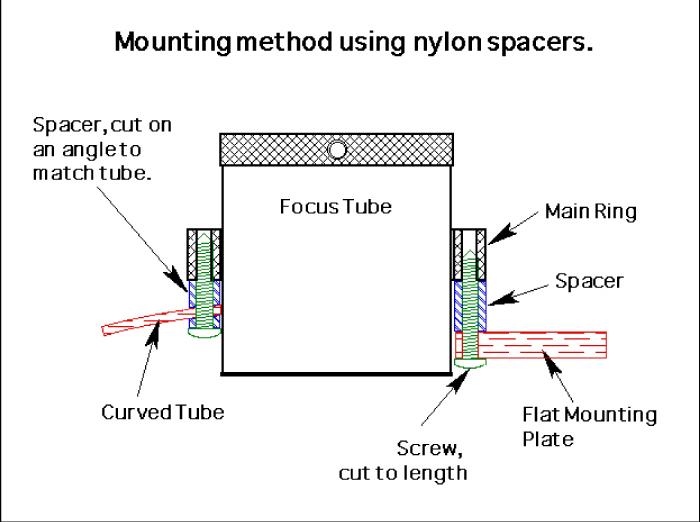

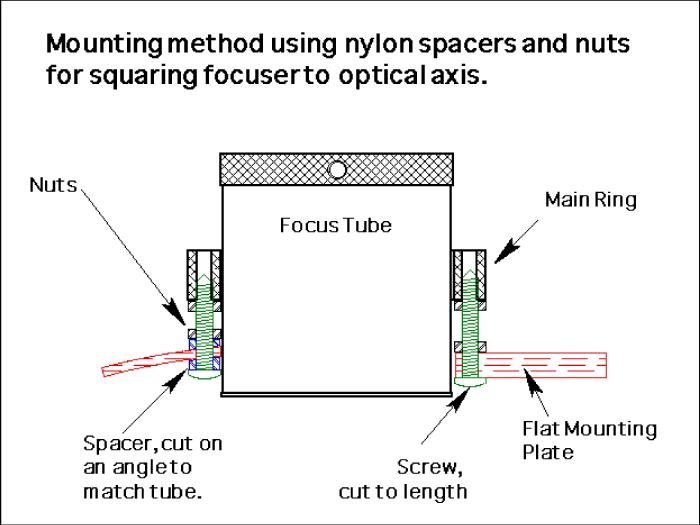

The Open Frame Design Focusers typically have some sort of mounting plate either built in or attached. While this may seem like a nice feature, it somewhat limits the installation flexibility of the focuser mounting location relative to the focal plane. With the open frame design of this focuser, the telescope maker now has the option of mounting the HC-2 at the best distance from the tube wall and, also, be able to change the vertical position easily. |

Flat vs Round Mounting Surface Obviously, the HC-2 is best suited for installation on a flat mounting plate. But with a little patience, the HC-2 can be fitted very well to a round tube. Illustrated below are several methods to mount the HC-2. Please note that the different sized spacers can be used in combinations to achieve the correct axial location. Many other methods are possible due to the open frame design. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Main Hole and Screw Holes The hole in both a curved tube or a flat plate mounting surface should be 2.375". This hole has to be cut accurately because if it is too small, it will interfere with the focusing tube. If it is too big, there will not be adequate material around the screw heads. To mark the three screw hole locations, remove the the bearings from the main ring and place main ring over the mounting plate hole. Alternately, the holes can be laid out on a 2.715" dia. bolt circle, (2.660" dia. on early HC-2 Main Rings), 120 degrees apart. The three screw holes in the mounting plate or tube should be drilled .166", diameter for the 8-32 mounting screws. |

General Maintenance The HC-1 should be kept clean for optimum performance. When focusing, if the slightest bump is felt, it is an indication of dirt under the bearings. If the focusing is not very smooth or slips and grabs, it is an indication of oil or grease on the focusing tube, which causes a variation in friction between the Teflon ball and the tube. In any case, simply loosen the adjusting screw, collapse the Teflon ball, and remove and clean the focusing tube. Also, whenever the two nuts holding the bearings are re-tightened, align the flats of the nuts so they will clear the lip on the bottom of the focusing tube. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Below are two sketches showing possible methods of mounting. |

||

|

||

|

||