|

||||||||||||||||

|

||||||||||||||||

|

|

|

||||||||||||||

|

||||||||||||||||

Stewart Piano Tuning Hammer |

||||||||||||||||

**Scroll down for the latest news** Steinway / Yamaha tips available. |

||||||||||||||||

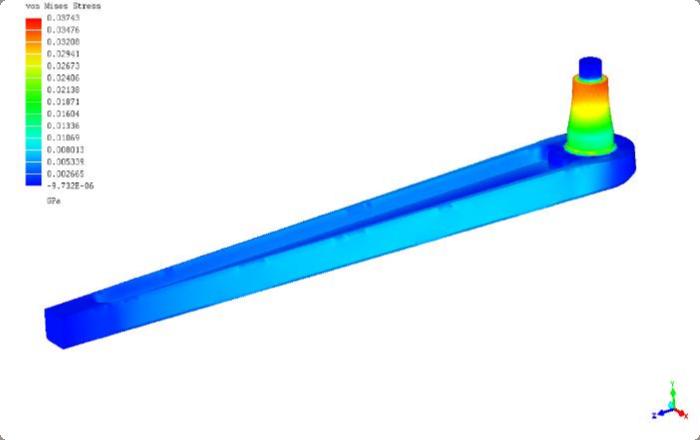

The Stewart Piano Tuning Hammer PTH-5-1 The Stewart PTH-5-1 will probably be the best tuning hammer you will ever tune with. Designed by the KineOptics design team, the Stewart Piano Tuning Hammer is made from aerospace materials and manufacturing techniques. The Aluminum Arm and Titanium Torque Shaft have been extensively analyzed using modern Finite Element Analysis software for material dimensions and thickness for maximum stiffness with minimal weight. When held, the Tuning Hammer has a good feel and balance to minimize fatigue during those long tuning sessions. The Titanium Torque Shaft projects 1 inch from the handle at a 5 degree angle. The Torque Shaft is set into the handle and located securely with an 8 sided modified spline and locked in with a screw. The Arm is CNC machined from aluminum and anodized a nice Dark Red. The I beam cross section was designed using Finite Element Analysis to reduce weight while keeping stiffness high. The Acetal Handle was designed to be comfortable in the hand and have maximum feel and control. All parts including our special tip are designed using CAD software and machined with CNC machines in our shop in Sequim Washington. Watch John Ruggero's review of the PTH-5-1 Read Ryan Peterson's review of the Stewart PTH-5-1 ________________________________________________________________________ ________________________________________________________________________ The Stewart Piano Tuning Tips Our Piano Tuning Tips are manufactured in our shop with a proprietary process that results in an extremely accurate and smooth internal tapered square feature. This special design and manufacturing method will provide a snug fit on the piano pin and the rounded edges greatly reduce the marking and scratching of piano tuning pins. We have done extensive measuring and testing of piano manufacturer's pins and some aftermarket pins for dimensional accuracy using micrometers, guages, and an optical comparator and have discovered quite a difference in the angle of the square taper between manufacturers and even pins from the same manufacturer. Working with Yamaha, we tested a group of new Yamaha pins and found that Yamaha pins have a slightly different geometry than most of the aftermarket pins we have measured. We have acquired a number of new Steinway Klinke Diamant pins and found that the angle of the tapered square is the same as Yamaha pins. We are now offereing one tip for both Steinway and Yamaha. This should suffice most needs as months of testing on different pianos and reports from customers verify this. Our testing has shown that the different sizes of pins are actually only the diameter, the square taper feature is essentially the same. A larger pin will have the square extend lower onto this larger diameter. This tip will still fit aftermarket pins, but not as well as they fit Steinway and Yamaha pins. ________________________________________________________________________ Pricing Stewart PTH-5-1: $325.00 with no tip Stewart Standard Tip: $80.00 We offer two sizes, shallow fit or deep fit. (only a few left) Stewart Steinway / Yamaha Tip: $80.00 Now in stock and available. We offer a return policy, please ask. ________________________________________________________________________ Ordering: Please contact us regarding your interest in the PTH-5-1. Please put PTH in the subject line to help us track orders. Include your address and what you would like to order. We will then calculate shipping cost and reply back. We can accept Checks and Paypal. Shipping: We normally ship UPS or USPS. For more information or to order: Call or E-Mail |

||||||||||||||||

|

||

The rectangular cross section of the Stewart PTH-5-1 provides positive rotational control when placing it on tuning pins. |

||

|

||

This image shows the torque tube set into the handle. This spline feature is an interference fit and makes the two parts essentially one piece. |

||

|

||

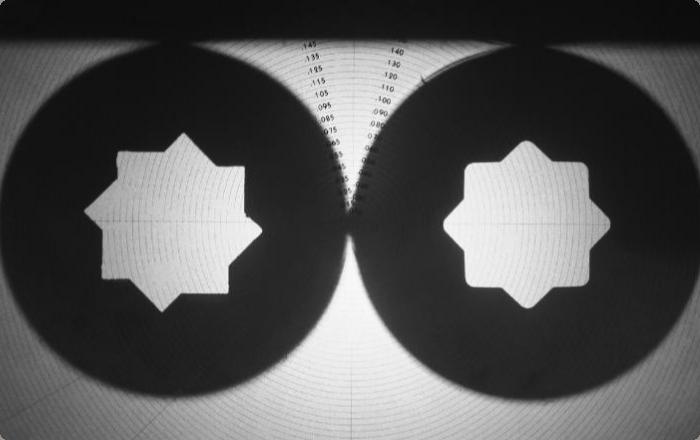

This image is of two tips. The one on the left is the worst tip we have ever seen. The tip on the right is our tip, manufactured in Sequim, Washington State. The image was taken in our optical profile projector. Notice the accurate profile of our tip and the rounded inside corners. This accurate, smooth profile will protect expensive tuning pins from marks. |

||

|

||

This picture is of the final FEA analysis of the PTH Arm after extensive design |

||

We have had some questions and here are the answers. 1: "Your tip looks great, but when tuning, it is an excellent fit on some piano pins, but a bit wobbly on other pins." Our tip is manufactured to very tight tolerances and we have made a QC gauge to test each one after manufacturing. The issue we have found is that there is variation in the piano tuning pins. There are several reasons which will result in a less than perfect fit. We have measured several of these variations and it is not just in the diameter or total angle of the square taper, but we have also measured a different angle and position of the square taper on each opposing pair of flats. This results in a tighter fit in one direction, but a bit loose 90 degrees to that. NOTE: We now have a special tip designed for best fit on Yamaha pins. 2: "On a few pianos I have tuned with your lever, the large size of the handle head interferes with the case on a few pins." There is no way around that. To get the stiffness and keep the weight low, the large diameter of the head has to exist to lower the stress, thus keeping it feeling very stiff. The Stewart PTH will be able to access all but a few pins on most pianos. Generally, one will be able to tune every pin with the PTH. But to get to those few pins that are close to and edge, one will have to use a lever with a longer reach, thinner head, or a tip extension. But what the PTH will do is tune with a feel and speed that will reduce your tuning time and increase your precision. 3: "The lever is great and extremely stiff and light, but I have anodized aluminum parts on my bike and they get scratched up" Yes, any anodized aluminum part will scratch and dent, but we needed to use aluminum to get the best balance between stiffness and weight. If you are like us and take pride in our tools, you can wrap the handle with some clear protective tape. The kind used for protecting paint on cars and bike frames. This is also recommended when one wants to protect the paint on the piano plate or any other surface on the piano that could be damaged accidentally from the hammer. 4: "Will other tips fit on your lever? Yes, as far as we know, every other tip we tried fits on our threads. 5: "Will your tips fit on other hammers? Yes, our tips will fit on other hammers. ___________________________________________ |

||